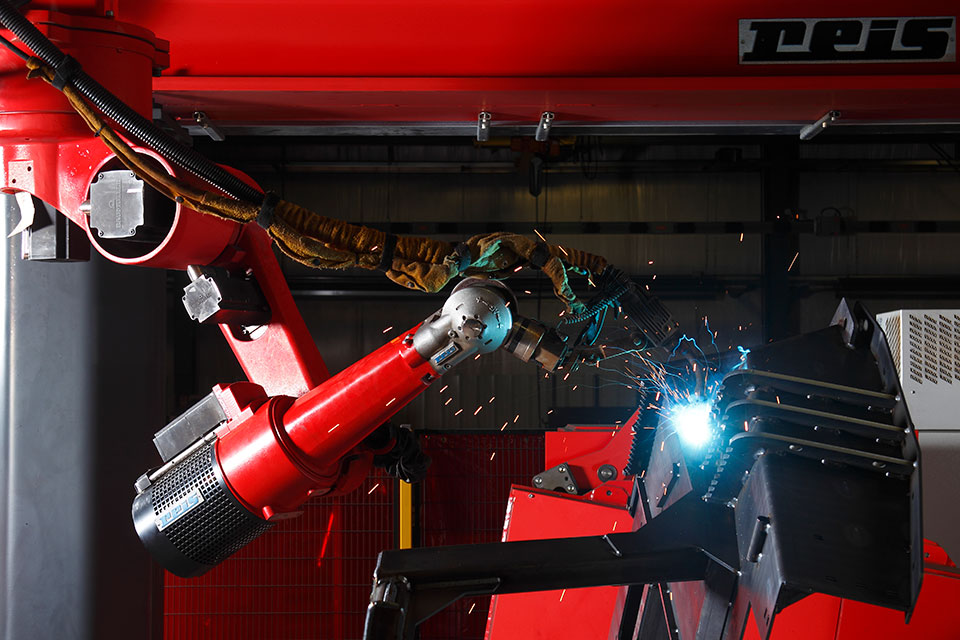

Certified Robotic Welding

Our robotic welding has grown as we continue to concentrate on complex and large volume weldments previously thought only possible at large OEM’s.

Our offline programming offers many advantages that save time and project costs for everyone.

- Perform reach studies to help with part and fixture design

- Quote estimated cycle times for more accurate quoting and manufacturing design recommendations

- Maximize robotic welding systems production while programming offline

- Trouble shoot program issues and improvement of arc on times for part programs

Our automation team was one of the first in North America to utilize a new advanced offline robotic welding software.

Some of our programs were even featured at Europe’s largest 2018 manufacturing trade show in Germany.

Robotics allows our customers the opportunity to continue to grow and leverage our automation as part of their business plan.