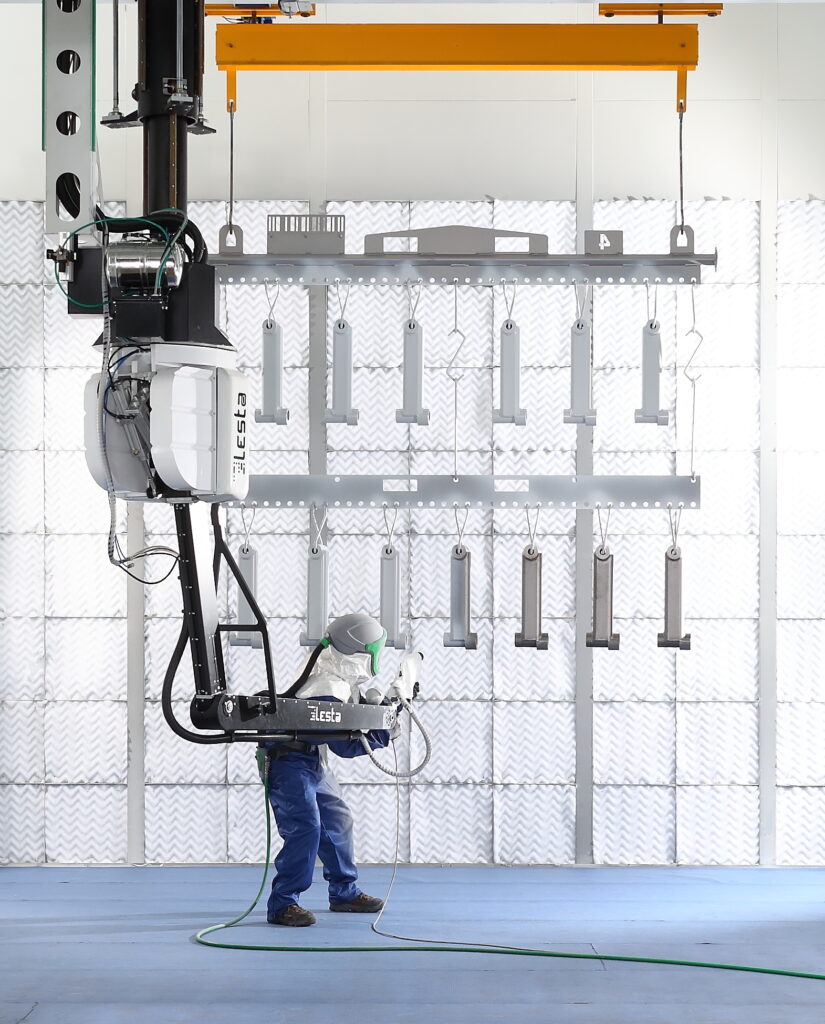

Day One Solutions for Robotic Painting and Finishing

Saving customers time allows for tremendous process improvement > A painting and finishing system’s ROI should begin at the moment it goes live.

SHARE WITH A COLLEAGUE

Derek DeGeest, President, DeGeest Corporation & LestaUSA, and Brad Ruppert, Engineering Manager and Applications Specialist for DeGeest, provided host Tyler Kern with all the details surrounding LestaUSA’s exciting “Day One” program.

“Day One was something that, as we launched LestaUSA, we wanted to make sure we offered our customers,” DeGeest said. “The self-learning robotic technology allows you to program a part in real-time and create programs rapidly. So, we can make programs as soon as we put them in. Most of the time, our customers are learning in our test lab and already making programs and already understanding how to make production parts before we even put it (the system) in.”

The Day One solution came about through early customer installs of the DeGeest and LestaUSA robots.

“We had a some customers at our integration center for training and run-off, and they’d get the programming done,” Ruppert said. “We’d get out to the field, and it’s not the same, because they haven’t set their parts up to be presented to that booth the same. To help this we’ve offer to take one of their parts and set up in our test lab as close to their real-life situation as possible. We develop the fixturing for them to use at their facility to present the part to the booth so that it’s the same every time.”

The customer is up and running within an hour after initial setup.

DeGeest and Ruppert’s desires for the Day One solution are all about making the installation of the customer’s new robot as seamless a transition as possible.

“Companies are looking at automation because they want to get the most out of the people they have,” Ruppert said. And the ability to produce on day one is that ultimate goal.

Be sure to subscribe to Manufacturing a Stronger Standard for the latest podcasts on Spotify and Apple Podcasts.