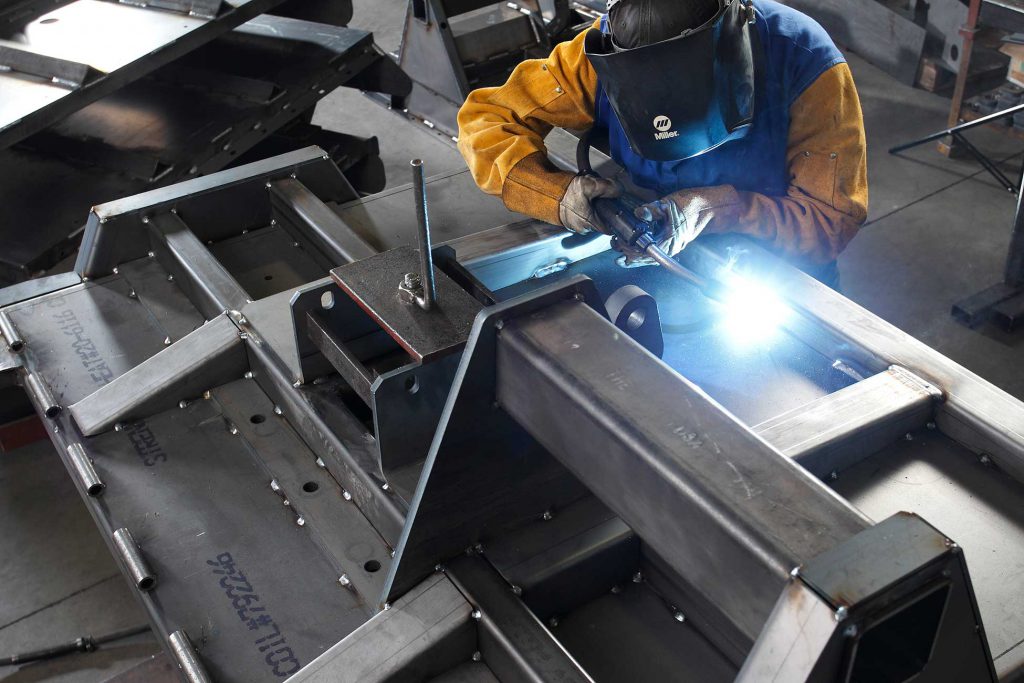

Certified Manual Welding

We work harder and smarter, which creates an environment where everyone contributes and is proud of what they produce.

We have the flexibility to move and adapt to your day to day needs and accommodate large weldments, fixtures and manipulators inside our 32 weld stations.

- We create in-house fixture designs in both free hand and complex 3D modeling software for tacking, welding and manipulating our weldments.

- We utilize many kinds of ergonomic and handling equipment that has evolved over the years to help our team work more efficiently: center of gravity rotational manipulators, powered rotational manipulators, lay on fixtures, and complex tab & slot fixtures

- For the past 5 years we have been working on a Welding Power Source Standardization Program for all our welding stations. This allowed us to develop a proprietary Welding Process Standards application system that can be utilized at any of our weld stations.

We are very proud of our welding efficiency and boast some of the highest average deposition in pounds of wire per employee in the industry.